Drum Concrete Mixer With Pump

Both diesel engine and electric motor available;

Simple electric control system with remote control;

Adopting proximity switch in hydraulic cylinder to change direction with non-touch;

Wear plate and cutting rings use high-wear materials.

Simple electric control system with remote control;

Adopting proximity switch in hydraulic cylinder to change direction with non-touch;

Wear plate and cutting rings use high-wear materials.

Related Products

-

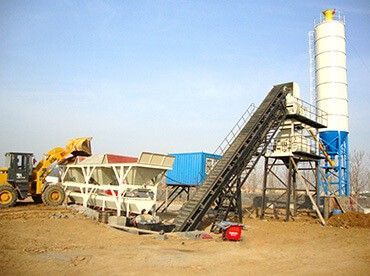

HZS25 Compact Concrete Batch Plant

HZS25 Compact Concrete Batch Plant

view detail -

HZS60 Stationary Concrete Batch Plant

HZS60 Stationary Concrete Batch Plant

view detail -

HZS90 Stationary Concrete Batch Plant

HZS90 Stationary Concrete Batch Plant

view detail -

YHZS25 Mobile Concrete Batching Plant

YHZS25 Mobile Concrete Batching Plant

view detail -

YHZS60 Mobile Concrete Batching Plant

YHZS60 Mobile Concrete Batching Plant

view detail -

YHZS100 Mobile Concrete Batching Plant

YHZS100 Mobile Concrete Batching Plant

view detail -

Super-Mobile Asphalt Mixing Plant

Super-Mobile Asphalt Mixing Plant

view detail -

Asphalt Drum Mixing Plant

Asphalt Drum Mixing Plant

view detail -

Asphalt Batch Mixing Plant LB Series

Asphalt Batch Mixing Plant LB Series

view detail

Get In Touch

If you have any suggestions or opinions about our products, please leave a message, and we will immediately answer your questions. Thanks for your support.